The Spark That Heats Your Home

Furnace ignitor replacement is one of the most common heating system repairs homeowners face during cold months. When your furnace won’t start or keeps shutting off, the ignitor is often the culprit.

Quick Answer: Furnace Ignitor Replacement Overview

- Function: Creates spark or heat to ignite gas burners

- Lifespan: 3-7 years depending on type and usage

- Common signs: No heat, clicking sounds, furnace won’t start

- Types: Hot surface ignitors (most common) and spark ignitors

- Professional recommendation: Due to gas and electrical safety concerns

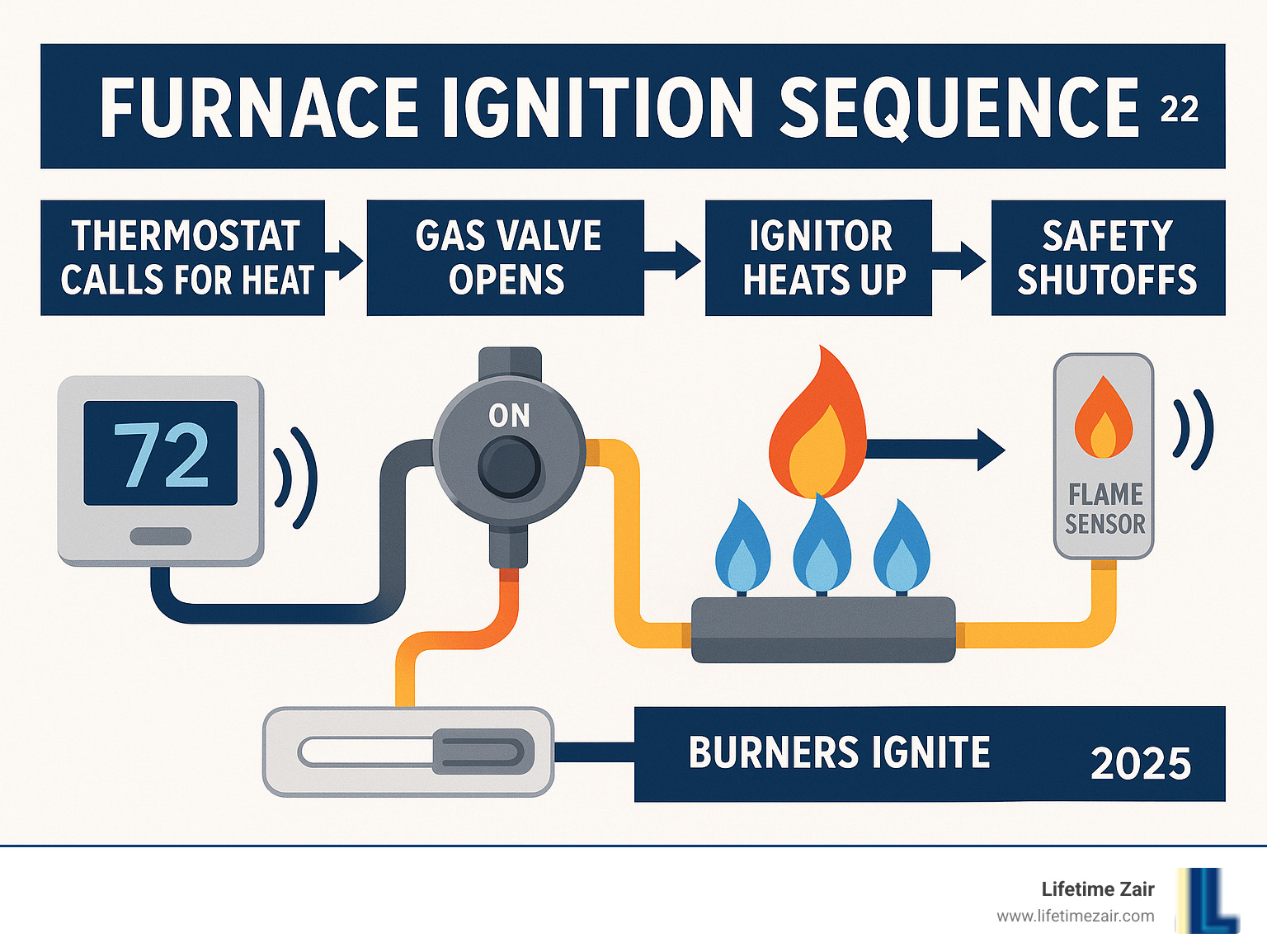

Your furnace ignitor is the critical component that starts the heating process every time your thermostat calls for heat. Modern furnaces typically use hot surface ignitors made of ceramic materials like silicon carbide or the more durable silicon nitride. These fragile elements heat up to around 2,500°F to ignite your gas burners.

When an ignitor fails, your furnace simply can’t create heat. The good news? A faulty furnace ignitor is “one of the most common reasons for heating systems to fail,” but it’s also “a relatively straightforward and affordable repair” according to HVAC professionals.

Understanding when your ignitor needs replacement – and whether you should tackle it yourself or call a professional – can save you from those unexpected cold nights and help you make the best decision for your home’s heating needs.

Signs Your Furnace Ignitor is Failing

Picture this: it’s a frigid winter morning, and you wake up to a house that feels more like an icebox than a cozy home. The thermostat shows your desired temperature, but your furnace is giving you the cold shoulder – literally. When your furnace won’t start, makes mysterious clicking sounds, or leaves you shivering despite running constantly, your ignitor is likely crying out for help.

Furnace ignitor replacement becomes necessary when you notice these telltale warning signs. The most obvious red flag is when your furnace simply won’t fire up. You might hear the familiar whoosh of the blower fan starting, but then… nothing. No comforting rumble of flames, just an eerie silence that leaves you reaching for extra blankets.

Those persistent clicking sounds are another dead giveaway. Think of it as your furnace’s version of a car that won’t start – it keeps trying to turn over but never catches. This repetitive clicking happens when your system attempts to ignite the gas burners but the ignitor isn’t hot enough to do its job.

Sometimes your furnace plays tricks on you by blowing cold air instead of the warm comfort you’re expecting. The fan runs enthusiastically, but without a working ignitor, those burners stay stubbornly unlit. If you’re experiencing this frustrating situation, you’ll want to check out our guide on Furnace Blowing Cold for more insights.

Short cycling is another sneaky symptom where your furnace starts its heating cycle, briefly creates some heat, then abruptly shuts down. This stop-and-start dance happens when the ignitor manages to light the burners initially, but the system detects something’s wrong and cuts off the gas supply for safety.

Modern furnaces are pretty smart and will often display error codes on their control panels when ignition problems occur. These diagnostic codes are like your furnace’s way of leaving you a helpful note about what’s bothering it. Ignition failure codes are among The Most Common Furnace Issues that homeowners encounter.

Visual Clues of a Bad Ignitor

Sometimes your ignitor wears its problems on its sleeve – or in this case, on its ceramic surface. If you can safely peek at the ignitor (always with the power turned off!), it might show you exactly what’s wrong.

A cracked ignitor is the most common visual sign of failure. These delicate ceramic or silicon components go through thousands of heating and cooling cycles, making them as brittle as an old cookie over time. Even a hairline crack means the ignitor can’t reach the scorching temperatures needed to light your gas burners.

White, chalky buildup on the ignitor surface acts like a blanket, preventing it from getting hot enough to do its job. This powdery coating can come from various airborne contaminants that settle on the ignitor over time.

Dark soot or carbon deposits tell a story of incomplete combustion or dirty burner conditions. These black marks aren’t just unsightly – they interfere with the ignitor’s ability to function properly.

Excessive burn marks or discoloration around the ignitor suggest it’s been working too hard, possibly overheating due to electrical issues or poor airflow conditions.

Common Causes of Furnace Ignitor Failure

Understanding why ignitors fail helps you prevent future problems and appreciate why these little workhorses eventually need replacement.

Age and normal wear top the list of ignitor killers. These components typically last between 3 to 7 years, enduring extreme temperature swings from room temperature to over 2,000°F countless times. Like a marathon runner’s knees, they eventually wear out from all that stress.

Electrical surges can zap your ignitor’s delicate components faster than you can say “power outage.” Voltage spikes or inconsistent electrical supply put extra strain on the ignitor’s internal elements.

Dirty air filters create a domino effect that hurts your ignitor. When filters get clogged, airflow becomes restricted, causing the entire system to work harder and run hotter than designed. This extra heat stress shortens the ignitor’s lifespan significantly.

Moisture and humidity can sneak into electrical connections or cause the ceramic body to develop stress fractures. While less common, water damage can quickly turn a healthy ignitor into a dud.

Accidental mishandling during previous repairs or maintenance can doom an ignitor before its time. These fragile components can crack from rough handling or fail prematurely if touched with bare hands during installation.

Poor maintenance habits contribute to many ignitor failures, which is just one example of What Happens If Your Furnace Isn’t Well Maintained?. Regular care keeps your entire heating system – including that crucial ignitor – running smoothly for years to come.

Understanding the Different Types of Furnace Ignitors

Think of your furnace ignitor as the match that lights your home’s heating system. But unlike the simple wooden matches in your kitchen drawer, furnace ignitors come in different varieties, each with their own personality and lifespan. Understanding which type lives in your furnace makes all the difference when it comes time for furnace ignitor replacement.

The vast majority of modern furnaces rely on Hot Surface Ignitors (HSI) to get the party started. These clever little devices work just like the heating element in your toaster – electricity flows through them, they glow cherry red, and that intense heat ignites the gas flowing from your burners. It’s simple, effective, and surprisingly reliable.

But here’s where things get interesting. Not all hot surface ignitors are built the same. The older generation uses silicon carbide, a ceramic-like material that gets the job done but has one major weakness – it’s incredibly fragile. Think of it as the delicate china of the furnace world. These silicon carbide ignitors crack easily from physical shock or the constant stress of heating up and cooling down. They typically last around 3-5 years before giving up the ghost.

The newer technology uses silicon nitride, and it’s a game-changer. These ignitors are much more robust and flexible than their brittle predecessors. In fact, newer silicon nitride ignitors can outlast the silicon carbide variety by two to seven times. If your furnace needs a new ignitor, silicon nitride is often worth the investment for its longevity.

Some older furnaces still use Intermittent Pilot Ignition systems. These work differently – when your thermostat calls for heat, an electric spark lights a small pilot flame first. That pilot flame then ignites the main burners, kind of like using a candle to light a campfire. Once the main burners are running, the pilot flame goes out until the next heating cycle. It’s more energy-efficient than keeping a pilot light burning constantly.

Spark Ignition systems cut out the middleman entirely. Like the igniter on your gas grill, they use a high-voltage electrical spark to directly light the main gas burners. No pilot light, no glowing element – just a good old-fashioned spark. These are less common in home furnaces but you’ll find them in some specialty applications.

| Ignitor Type | Material | Lifespan (Typical) | Common Furnace Type |

|---|---|---|---|

| Hot Surface Ignitor (HSI) | Silicon Carbide (older) | 3-5 years | Older high-efficiency gas furnaces |

| Hot Surface Ignitor (HSI) | Silicon Nitride (newer, more durable) | 5-7+ years | Modern high-efficiency gas furnaces |

| Intermittent Pilot Ignition | Metal electrode, ceramic insulator | Varies (long) | Mid-efficiency gas furnaces (older models) |

| Spark Ignition | Metal electrode, ceramic insulator | Varies (long) | Some gas furnaces, water heaters, boilers |

Most furnace ignitors have a lifespan of 3 to 7 years, regardless of type. The key is knowing what you’re working with when replacement time comes around. Your furnace manual or a quick look at the existing ignitor can help identify which type you have, making your furnace ignitor replacement process much smoother.

DIY vs. Professional Furnace Ignitor Replacement: What to Consider

When your furnace ignitor gives up the ghost, you might find yourself staring at YouTube tutorials and thinking, “How hard could this be?” While we admire the DIY spirit, furnace ignitor replacement sits in that tricky territory where enthusiasm can meet some pretty serious safety concerns.

Let’s be honest – working on your furnace means dealing with both gas lines and electrical components. That’s like juggling fire and lightning, and frankly, most of us would rather leave that to the professionals. Electrical shock and gas leaks aren’t just inconveniences; they’re genuine safety hazards that can put your family and home at risk.

Then there’s the matter of component fragility. Hot surface ignitors, especially those older silicon carbide models, are about as delicate as fine china. One wrong move, and your brand-new replacement part becomes an expensive pile of ceramic fragments. It’s frustrating enough when your furnace isn’t working – imagine breaking the fix before you even get started.

Having the proper tools is another consideration. You might have screwdrivers and basic equipment, but do you have a multimeter to properly diagnose whether the ignitor is actually the problem? Without the right diagnostic tools, you could be replacing a perfectly good ignitor while the real culprit lurks elsewhere in your system.

Here’s something many homeowners don’t consider: voiding warranty. If your furnace is still covered under manufacturer warranty, DIY repairs can sometimes invalidate that protection. Professional installation keeps your warranty intact, which is why Proper Furnace Installation Matters from day one.

Risks of Improper Replacement

When furnace ignitor replacement goes wrong, the consequences can range from mildly annoying to genuinely dangerous. Let’s walk through what can happen when good intentions meet inexperience.

Damage to new ignitor is probably the most common mishap. Remember how we mentioned these components are fragile? Well, oils from your skin can actually create hot spots on the ignitor element, causing premature failure. Even the gentlest handling requires clean gloves and careful technique.

Furnace malfunction is another headache waiting to happen. Maybe you get the ignitor physically installed, but if the wiring isn’t quite right or the positioning is off, your furnace might cycle erratically or fail to ignite consistently. What started as a simple repair becomes an ongoing reliability issue.

The most serious concern is safety hazards. Improper connections can lead to gas leaks, which create fire and explosion risks. Electrical mistakes can cause shorts, fires, or carbon monoxide issues. These aren’t just repair problems – they’re life-threatening situations that can endanger your entire household.

Inefficient operation might seem minor compared to safety risks, but a poorly installed ignitor can cause your furnace to work harder than necessary, driving up energy bills and shortening the system’s lifespan. This is exactly why regular maintenance is so crucial, as explained in Why Schedule Furnace Service?.

When to Call a Professional

So when should you set down those tools and pick up the phone? We recommend calling a professional for furnace ignitor replacement in several key situations.

If you have any uncertainty of diagnosis, it’s time to call in the experts. Maybe you replaced the ignitor and your furnace still won’t cooperate. A trained technician can quickly identify whether you’re dealing with a flame sensor issue, gas valve problem, or something else entirely.

Lack of proper tools is another clear signal. Without a multimeter and other diagnostic equipment, you’re essentially working blind. Professional technicians come equipped with everything needed to test, diagnose, and repair your system properly.

Discomfort with electrical/gas work should never be ignored. If the thought of working around gas lines or high-voltage components makes you nervous, trust that instinct. Your safety and peace of mind are worth more than any potential savings.

When your furnace still under warranty, professional service protects that valuable coverage. Manufacturer warranties often require certified technician installation to remain valid.

Complex modern furnaces with sophisticated control systems and high-efficiency features need specialized knowledge. These aren’t the simple furnaces of decades past – they’re computerized systems that require proper training to service safely.

Our team specializes in comprehensive HVAC Troubleshooting and can quickly identify the root cause of any heating issue, ensuring your family stays warm and safe all winter long.

The Professional Furnace Ignitor Replacement Process

When you call a professional for furnace ignitor replacement, you’re getting more than just a part swap – you’re getting expertise, safety protocols, and peace of mind. Our technicians arrive equipped with everything needed to diagnose and fix your heating system properly.

A professional technician comes prepared with specialized tools that most homeowners don’t have lying around. The multimeter is perhaps the most important tool – it allows accurate testing of electrical components to confirm the ignitor is actually the problem. Along with screwdrivers, nut drivers, and insulated gloves for safety, technicians also bring flashlights for good visibility and wire strippers if any custom wiring work is needed. Most importantly, they bring the correct replacement ignitor matched to your specific furnace model.

The professional process follows a strict safety-first approach. Before touching anything, the technician shuts off both power and gas to eliminate any risk of shock or gas leaks. Then comes the diagnostic phase – even if you’re certain the ignitor is bad, a good technician will verify this with proper testing rather than making assumptions.

Part matching is crucial and often overlooked by DIY attempts. Furnaces come in countless makes and models, and each requires a specific ignitor type. A professional knows how to identify the exact replacement needed, whether it’s a silicon carbide or silicon nitride hot surface ignitor, and ensures it’s compatible with your system’s voltage and mounting configuration.

The installation itself requires a delicate touch, followed by comprehensive system testing to ensure everything works perfectly. This methodical approach is what separates professional service from guesswork.

Step-by-Step: How a Technician Replaces the Ignitor

Watching a professional handle furnace ignitor replacement is like seeing a well-choreographed dance – every move is deliberate and safe. Here’s what happens during a typical service call.

The safety shutdown comes first, always. The technician locates your furnace’s circuit breaker and switches it off, then closes the manual gas shut-off valve. No shortcuts here – gas and electricity demand respect.

Accessing the burner assembly means carefully removing the furnace’s lower access panel. The ignitor is typically visible once this panel comes off, usually mounted near the burners where it can effectively ignite the gas.

The old ignitor removal requires gentle precision. After disconnecting the wire harness that provides power to the ignitor, the technician removes the mounting screws holding it in place. These screws might be Phillips head or require a nut driver, depending on your furnace design.

Installing the new ignitor is where experience really shows. Professional technicians handle these fragile components with clean gloves to prevent skin oils from contaminating the surface. They know exactly how to position the ignitor for optimal performance and secure it without over-tightening the screws.

The reconnection and testing phase is thorough. After plugging in the wire harness and replacing the access panel, the technician restores gas and power. They then call for heat at the thermostat and carefully observe the entire ignition sequence. They’re watching for proper ignitor glow, reliable gas ignition, and smooth furnace operation.

This systematic approach ensures your furnace ignitor replacement is done right the first time. It’s the same attention to detail we bring to our complete Furnace Installation Process and every repair we perform.

Frequently Asked Questions about Furnace Ignitors

Over the years, we’ve answered countless questions about furnace ignitors from homeowners just like you. These three questions come up time and time again, so let’s clear up the confusion once and for all.

How long does a furnace ignitor typically last?

The honest answer? It depends, but you can generally expect your furnace ignitor to last anywhere from 3 to 7 years. Think of it like the tires on your car – how long they last depends on how much you drive and the conditions you face.

Hot surface ignitors work incredibly hard, heating up to scorching temperatures and then cooling down thousands of times throughout their life. Those older silicon carbide models are particularly vulnerable to this constant thermal stress. They become brittle over time, kind of like how a rubber band eventually snaps after you stretch it too many times.

The good news is that newer silicon nitride ignitors are much tougher cookies. They’re designed to handle all that heating and cooling without throwing in the towel as quickly.

While you can’t prevent an ignitor from eventually wearing out (it’s just part of life!), staying on top of regular maintenance can help your entire system run more smoothly. Following our Fall and Winter Furnace Maintenance Tips and Tricks won’t make your ignitor immortal, but it can help catch problems before they leave you shivering in the dark.

Can a dirty flame sensor be mistaken for a bad ignitor?

Oh, absolutely! This is one of those “gotcha” situations that trips up even experienced DIYers. A dirty flame sensor can perfectly mimic the symptoms of a failed ignitor, and it’s frustrating when you think you know what’s wrong.

Here’s what happens: your ignitor does its job beautifully, glowing hot and lighting the gas burners. But then, just seconds later, everything shuts down. You might hear clicking sounds, or the furnace might keep trying to restart over and over again.

The culprit? A flame sensor that’s coated with soot or carbon buildup. This little safety device is supposed to confirm that there’s actually a flame burning after ignition. When it can’t “see” through all that grime, it panics and tells the furnace to shut off the gas supply immediately.

So your ignitor might be working perfectly fine – it’s just that the flame sensor can’t do its job properly. It’s like trying to look through a dirty window; everything might be fine on the other side, but you can’t tell because your view is blocked.

Is it okay to touch a new furnace ignitor with bare hands?

Please, please don’t! This is one of those mistakes that can turn a simple repair into a headache. Never touch the ceramic element of a hot surface ignitor with your bare hands.

Here’s why: the oils from your skin might seem harmless, but they’re like kryptonite to ignitors. When that ignitor heats up to over 2,000 degrees, those oils create weak spots – think of them as fingerprint-shaped time bombs. These hot spots can cause the ignitor to crack or burn out almost immediately, sometimes even during the first heating cycle.

It’s heartbreaking when someone carefully installs a new ignitor, only to have it fail right away because of this simple mistake. Professional technicians always wear clean gloves when handling new ignitors, treating them like the delicate components they are.

If you accidentally touch one, don’t panic – just clean it gently with a soft cloth and some rubbing alcohol before installation. But honestly, this is just one more reason why furnace ignitor replacement is often best left to the professionals who handle these fragile parts day in and day out.

Stay Warm with Reliable Furnace Service

When your furnace ignitor gives up the ghost on the coldest night of the year, it’s more than just an inconvenience – it’s a race against the dropping temperatures. The good news? Furnace ignitor replacement is one of those heating problems that’s completely fixable, and you don’t have to suffer through a chilly house while you figure it out.

Understanding how ignitors work and recognizing the warning signs certainly helps you make informed decisions about your home’s heating system. But here’s the thing – knowing about the process and actually performing a safe, reliable repair are two very different animals. Your family’s warmth and safety depend on getting this repair done right the first time.

That’s where professional expertise makes all the difference. A qualified technician brings the right tools, proper safety protocols, and years of experience to ensure your furnace ignitor replacement goes smoothly. They can quickly diagnose whether it’s truly the ignitor causing your troubles or if there’s another culprit hiding in your system. Plus, you get the peace of mind that comes with knowing the job was done safely and correctly.

From Dallas to McKinney, Plano to Lewisville, and across all our service areas in North Texas, homeowners trust our team at Lifetime Zair to get their heat running again when they need it most. We understand that furnace problems don’t wait for convenient times, and we’re committed to helping you stay comfortable through whatever winter throws your way.

Don’t let a faulty ignitor keep you bundled up in blankets inside your own home. If you’re experiencing any of the warning signs we’ve discussed – from mysterious clicking sounds to a furnace that just won’t start – it’s time to call in the professionals. For expert diagnosis and HVAC service in Dallas, TX and surrounding communities like Addison, Carrollton, Coppell, Frisco, and Plano, contact our team today. We’re here to help restore your home’s warmth and your peace of mind.